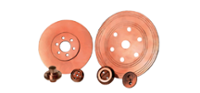

Spot Welding Electrodes

This is a brief presentation of the various spot welder cap materials supplied by weldtron and an endeavour to assist the user to select the best type of spot welder cap for his application.

It is an accepted norm to adopt cap & shank type of spot welding electrode for large requirements of spot welding internationally. This stems from the inherent advantages of caps which are low cost and higher productivity. Spot welder caps are commonly manufactured by cold heading which results in a double edged advantage of lower material consumption for manufacture (translating into lower costs) and higher mechanical properties like higher hardness, higher tensile strength etc due to intense cold working.

CHROMIUM ZIRCONIUM COPPER SPOT WELDER CAPS

- This is the basic cap material having a composition of 1% Chromium, 0.1% Zirconium; balance Copper – nominal.

- The nominal hardness of a cold forged Chromium Zirconium Copper cap is 85HRB, which results in long working life of the cap.

- The Zirconium in the cap prevents brassing up during welding of galvanized steels.

- Since it is Weldtron’s most popular cap material, standard designs are always available ex stock off the shelf.

- It is the lowest cost spot welding cap material.

- Chromium Zirconium Copper has a large application window and can be used for welding majority of jobs including plain Cold rolled and cold annealed steels, galvanized steels, Nickel steels and Terne coated steel sheets.

ZIRCONIUM COPPER SPOT WELDER CAPS:

This is a cap material having composition of 0.1% -Zirconium; balance – Copper nominal.

- The nominal hardness of a cold forged Zirconium Copper caps is 75 HRB.

- The Zirconium content in the cap discourages the zinc in the galvanized steel to alloy with the Copper in the cap and form brass. These caps also eliminate the sticking problem experienced during welding coated steels.

- Weldtron stocks caps as per Toyota’s design – T16Z & T13Z. Since we stock large quantity of raw materials in the form of barstock, caps can be produced with short lead times.

- It is a low cost spot welder cap material.

- Zirconium Copper caps are most suited for welding galvanized steels and other coated steels.

Projection/ Nut Welding Electrodes

Weldtron supply standard projection welding electrodes for M6, M8, M10, M12 nuts. Weldtron projection welding electrodes are provided with a self-insulating pin made out of composite materials having high hardness for locating nuts. These pins have very high resistance to aberrations which in turn gives long life. Also the electrodes will have a Tungsten Copper facing. The Tungsten Copper facing has very high wear resistance, results in longer life of electrode. These electrodes are available off the shelf any time

Apart from M6, M8, M10, M12 projection welding electrodes, other projection welding electrodes for different type of nuts are available on request.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.JPG_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.png_t.jpg)

.png_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.png_t.jpg)

.png_t.jpg)

.png_t.jpg)

.png_t.jpg)